| Criteria | Particle board | Prenel |

|---|---|---|

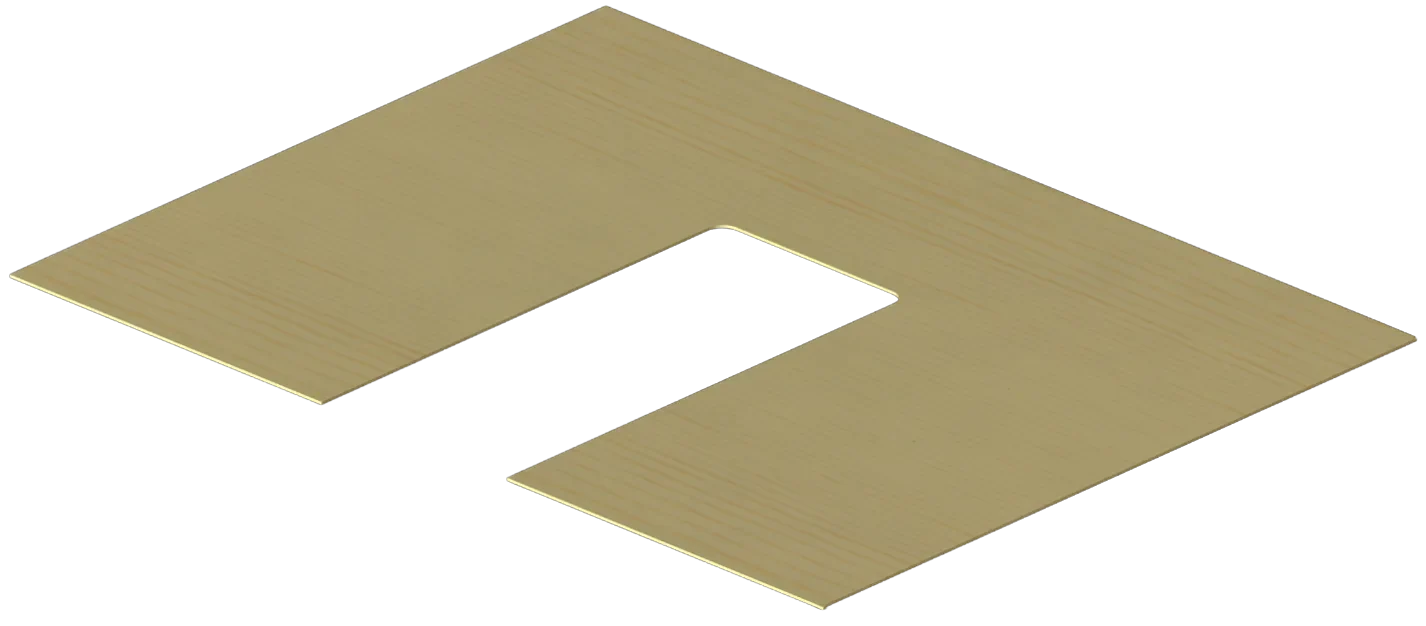

| Weight | Heavy | 70% lighter |

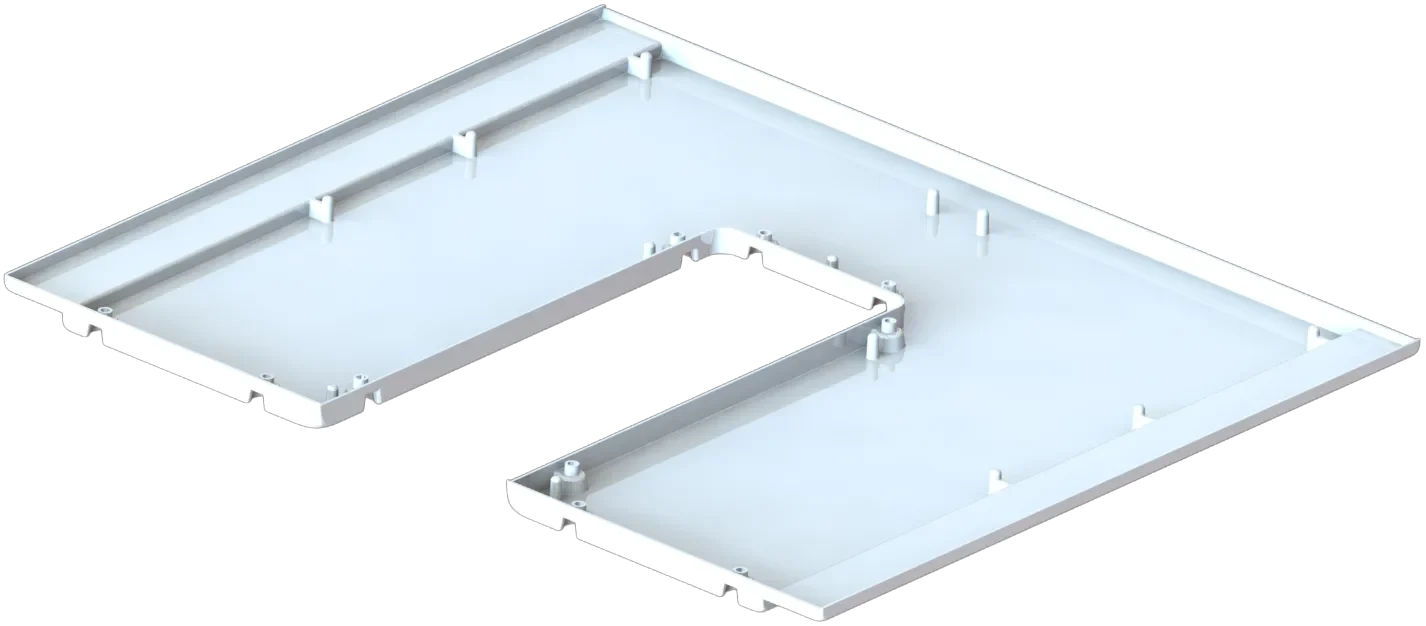

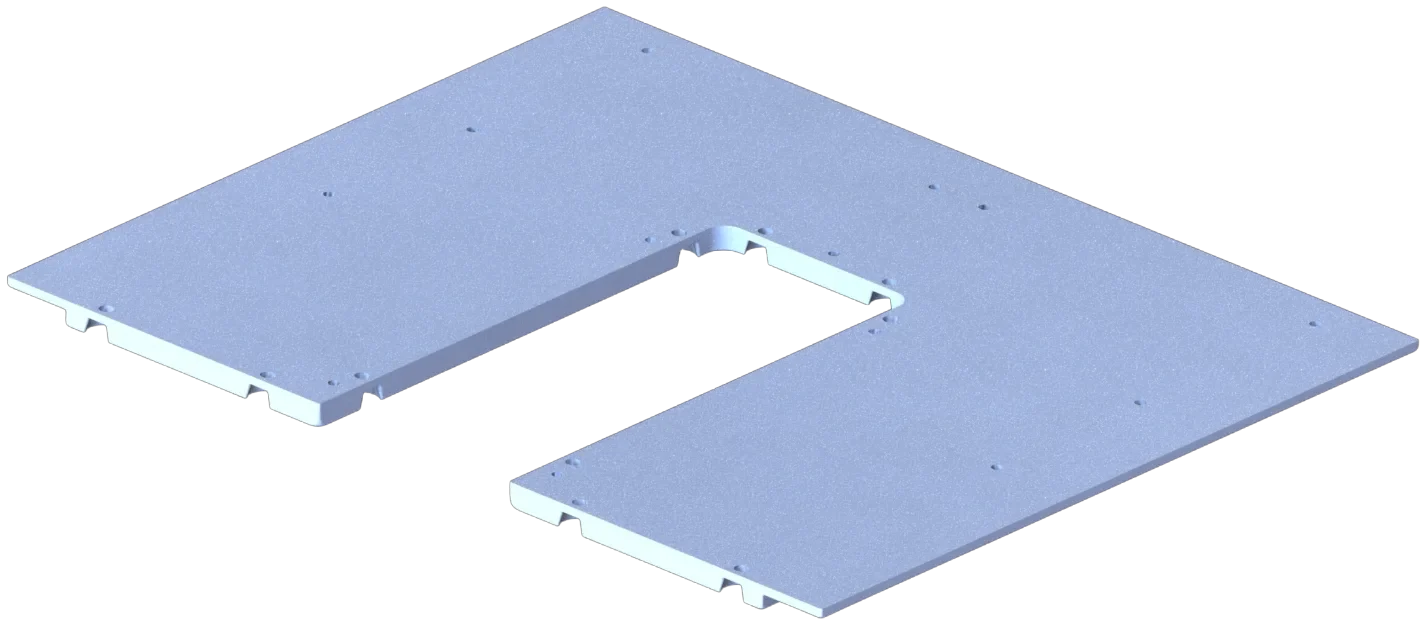

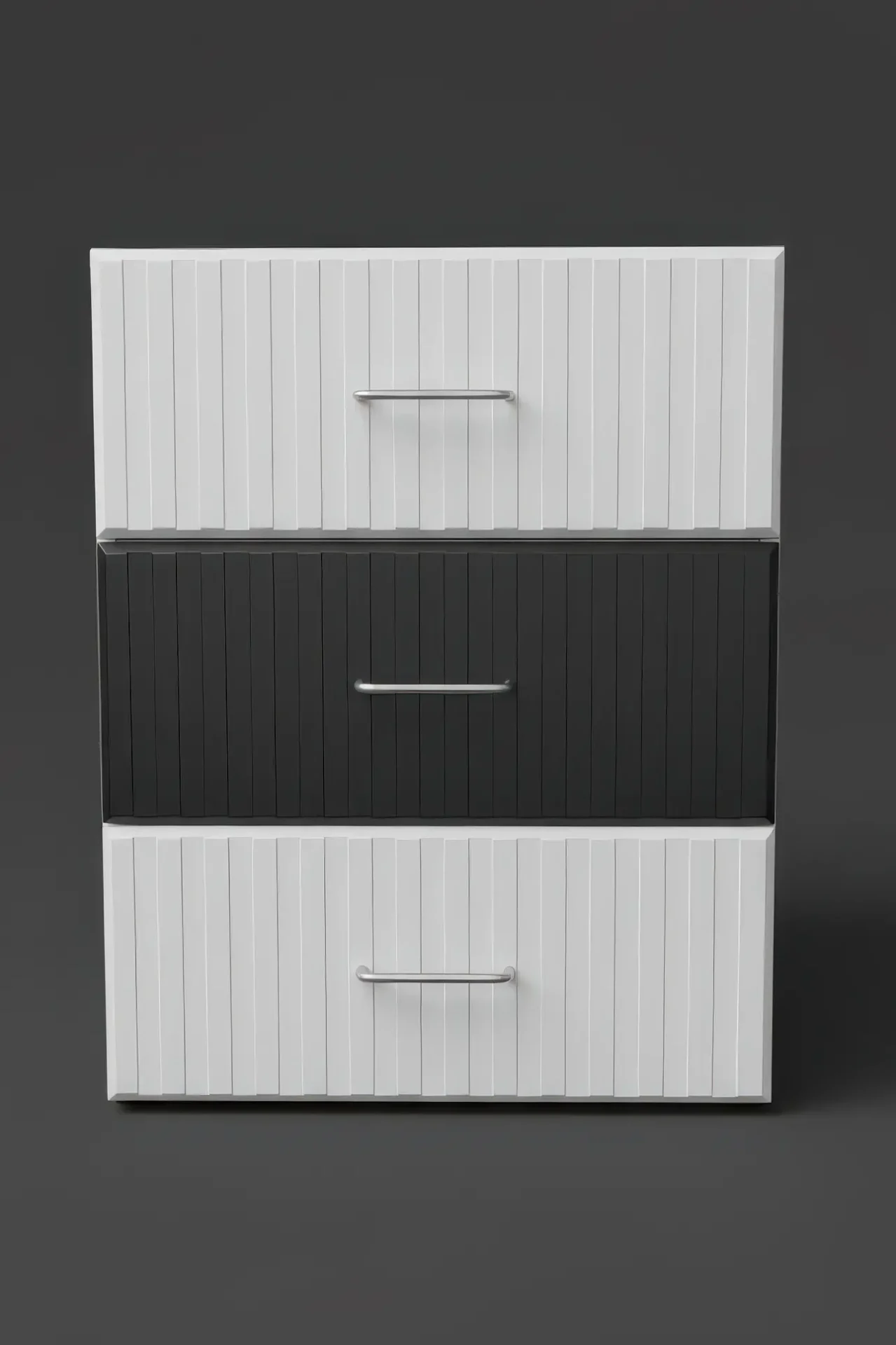

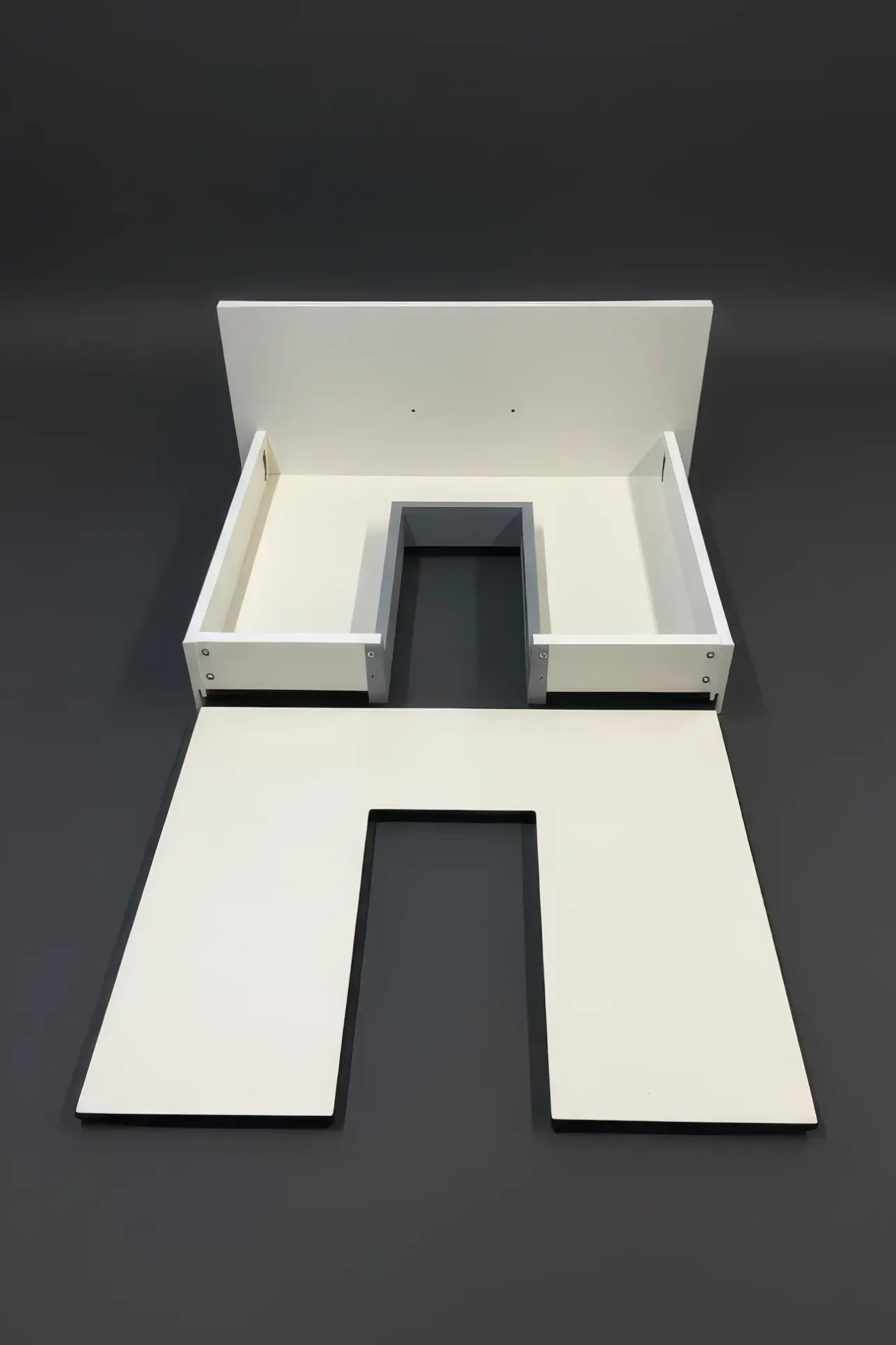

| Design options | Highly limited, 2D only | Unlimited 3D forms |

| Process steps | Many, labor-intensive | Reduced by 40% |

| Logistics costs | High | Reduced by 30% |

| Moisture resistance | Sensitive, requires additional protection | Integrated, permanent |

| Sustainability | Formaldehyde, hazardous waste | Formaldehyde-free, resource-efficient |

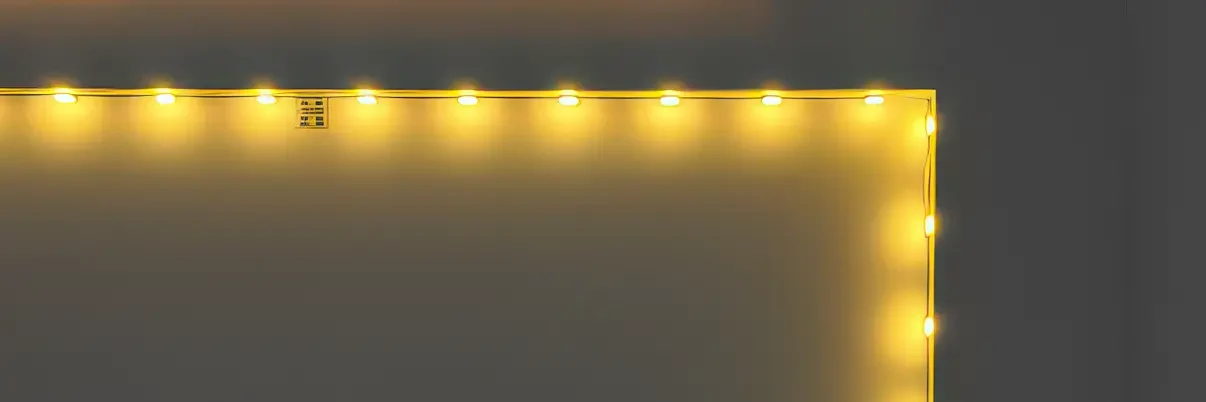

| Technical integration | Virtually impossible, very labor-intensive | Power, magnetics, electronics, LEDs |

prenel gmbh

Sennemahd 6

6840 Götzis, AUSTRIA

Telefon: +43 660 3506005

E-Mail: mail@prenel.eu